The cables used in Food & Beverage Industry must have a " Hygienic Design" "H.DE" and must comply with very strict safety protocols to prevent cross-contamination and maintain levels of mechanical, thermal, chemical safety required by operating standards; must be high temperature and corrosion resistant, Hygienic Design Compliant "HDC", suitable for hybrid lines, FDA approved.

H.DE-food

Control cables: robust, halogen-free, microbes/detergents/coolant water-soluble agents resistant, suitable for steam cleaning, for installation in automatic food and beverage plants, wheat milling, dairy processing, food packaging, slaughterhouses and meat packing, cold rooms, for light tensile load with free movements, in dry, humid and wet environments, NOT for outdoor underground installations.

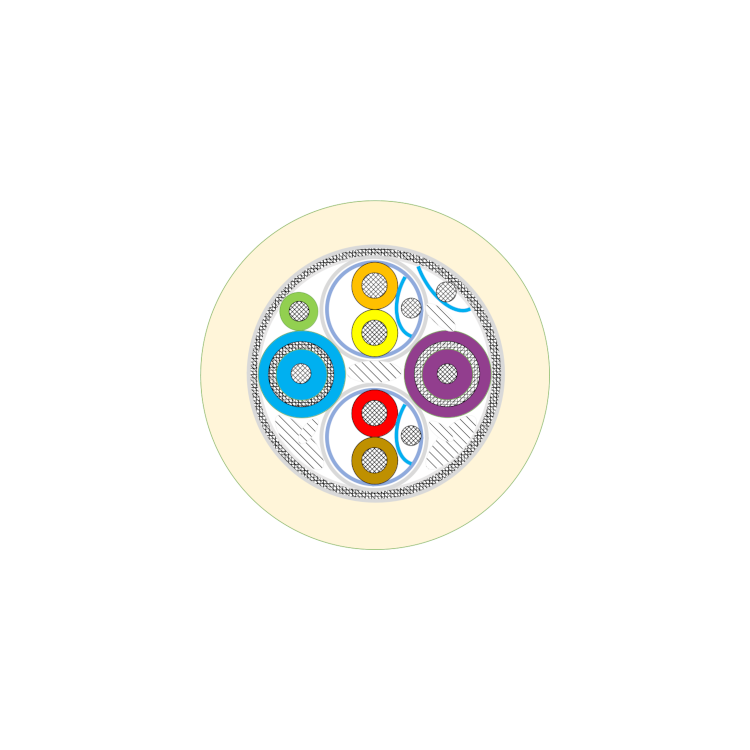

H.DE-S-food

Control cables: robust, halogen-free, microbes/detergents/coolant water-soluble agents resistant, suitable for steam cleaning, for installation in automatic food and beverage plants, wheat milling, dairy processing, food packaging, slaughterhouses and meat packing, cold rooms, for light tensile load with free movements, in dry, humid and wet environments, NOT for outdoor underground installations. Shielded for use in data signal transmission without interference, in environment with strong electromagnetic interferences.